Areas of work

- Mechanical design

- Static & Dynamic FEA

- Equipment automation

- Project management

- Fault and equipment diagnosis

- Reverse engineering

- Commissioning and manufacturing

- Process optimization

- Supplier development

About US

Who we are?

We are a group of engineers and professionals from the Argentine. It has brought us together our love for engineering and passion for solving problems, overcoming obstacles and creating new instruments that add value to the world. It is this passion and positive energy that established us not only as colleagues at Volping, but also as friends. We are very grateful to have been able to turn our training into a profession that has finally become a way of life.

Why do we do it?

We understand that each project is unique and we believe that with our knowledge we can help each one of them contribute a small grain of sand to improve the world in which we live; considering the environment, the safety of people and the efficient use of our natural resources. In this way, we specialize in providing personalized solutions that adapt to the specific needs of each client, reducing costs while generating a positive change on the planet. Whether it is innovative design, structural analysis or efficiency improvements, we are committed to delivering results that make a difference in all the aforementioned aspects.

Why choose us?

With years of experience in the sector, our team has in-depth knowledge and exceptional technical skill. Each project is approached with mastery and creativity to overcome the most demanding challenges.

In a constantly evolving world, we invest in the latest mechanical engineering technologies and tools. This allows us to stay at the forefront of trends and offer efficient, high-quality solutions. Quality is our top priority. We strive to exceed expectations and set standards of excellence; We also believe in close collaboration with our clients. Your vision is our guide, and we work hand in hand to transform ideas into tangible realities. Transparency and open communication are essential at every step of the process.

Our Work

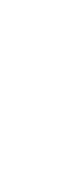

Water treatment - Loma Alta

For a water treatment plant in Loma Alta, Patagonia Argentina, we generate the P&ID, 3D CAD, equipment position and manufacturing plans for all the piping of the plant following the most demanding regulations.

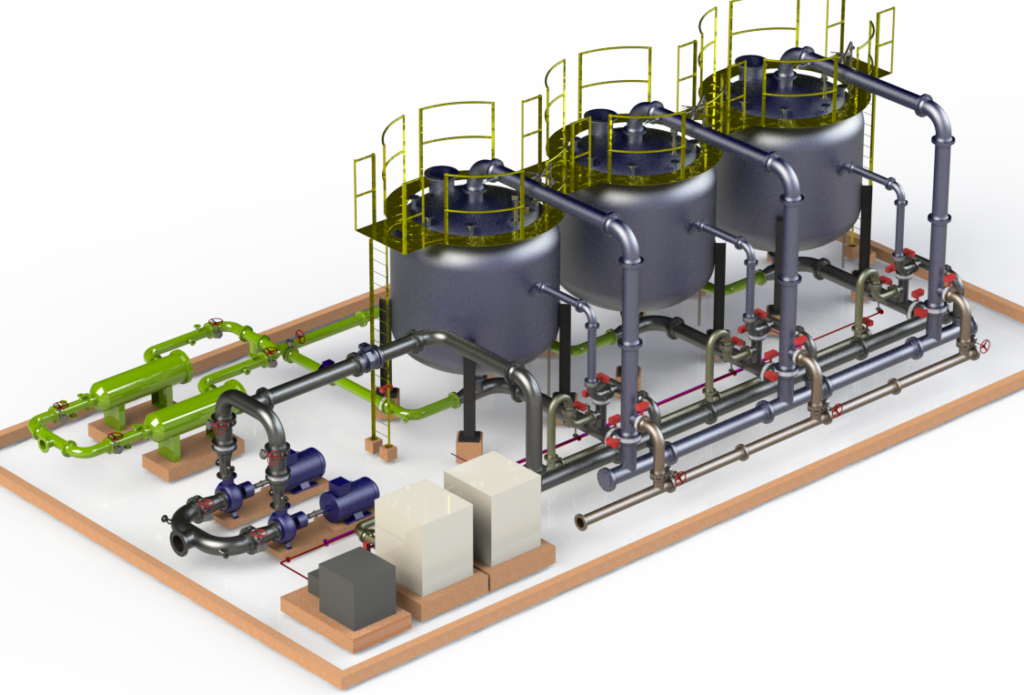

HOT OIL Truck - Neuquén

We traveled to Neuquén in Argentine Patagonia, where we relieved a truck used to clean paraffin deposited in oil extraction tubes. We did the entire reverse engineering process: We generated the CAD, manufacturing plans, optimized the structure and location of the equipment. In addition, we generate the purchase list of all the components for manufacturing and re-size the equipment to optimize costs and functionality.

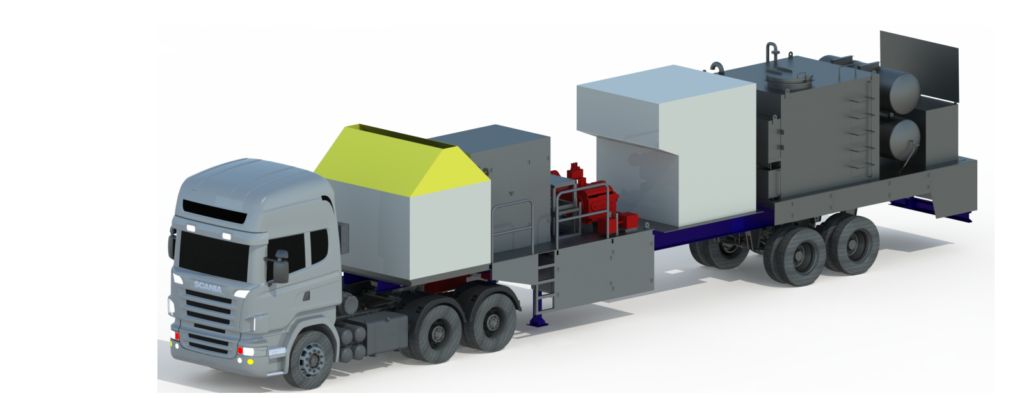

Agricultural Drone

We dimensioned and structurally verified the entire transmission train of an agricultural drone used to dose 20 liters of fertilizer in large fields. It was commanded by a 21.5 HP 4T gasoline engine.

Beer Filler Automation

Here we implement a system of solenoid valves controlled by a PLC and we program a PLC with an HMI interface to automate a beer bottle filling process.